Make Any Length You Want On Site!

Form-A-Tube® strips are supplied in standard 4-ft long pieces, longer pieces can be ordered as well. As shown here, pieces of different lengths can be connected (by staggering the joints) to make a tube of virtually any length. For example, you acn make a 20-ft tall tube from 1-ft long pieces!

Likewise, if required, openings can be easily created along the height of the tube to accommodate protruding attachments such as pipe penetrations.

Pile Encapsulation (Column Repair)

These 24-inch diameter steel piles were corroded over a height of 12-feet. The contractor used 14-ft long strips to extend 1-ft above and below the corroded zone. 14 strips were connected to create a sheet that was wrapped around the pile. This created a 14×2=28 inch diameter tube. Ratchet straps were used at 1-ft spacing along the height of the tube before it was filled with grout.

In this application, the ribbed surface is facing inwards and it locks into the grout, resulting in a permanent protection barrier (encapsulation) for the piles.

Timber Pile or Column Repair

This handyman homeowner repaired his 12-inch diameter timber pile that was rotting at and below ground level. 8 pieces of Form-A-Tube® each 3-ft long were assembled to create a 16-inch diameter tube. Ratchet straps were tied around the tube prior to placement of concrete. As you note a short piece of Form-A-Tube® can be inserted by sliding it into place after the bottom of the tube is filled. Then the remaining height of the tube is filled.

Form-A-Tube® - Infrastructure Innovation by Prof. Mo Ehsani

Form-A-Tube® is the latest product developed by Prof. Mo Ehsani that can greatly simplify some of the tasks regularly encountered in the construction industry. Unlike conventional forms that are made with cardboard and must be discarded in landfills after one use, Form-A-Tube® is made from recycled products and can be used many times — making it a green and sustainable product for the construction industry. The product has two distinct applications as described below.

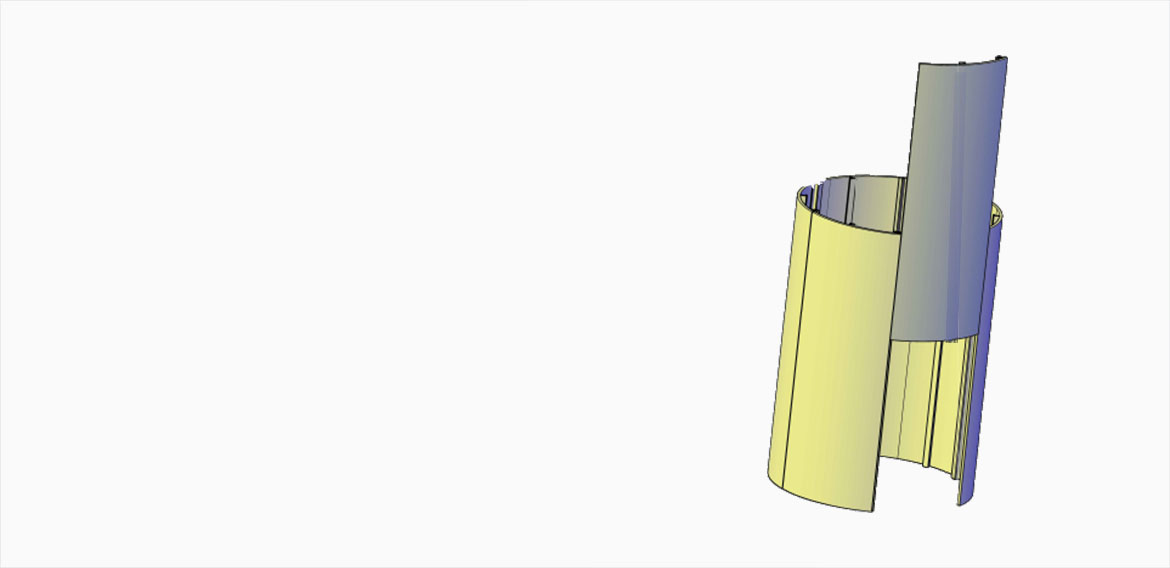

Reusable Concrete Form

In this case the strips of Form-A-Tube® are cut to the desired length and snapped together with the smooth surface facing inward to create a form for casting concrete columns, posts, etc. The form can be removed after the concrete hardens and it the PVC strips can be cleaned and stored for reuse in the future. The smooth surface of the panels prevents them from bonding to concrete while providing a very smooth finished concrete surface for the column. When it is necessary to repair a column or piling in an existing building or bridge, the panels can be wrapped around the existing column to create an annular space that can be filled with concrete or grout.

Stay-in-Place Form

In this application, for example for pile encapsulation or repair of damaged submerged piles, the Form-A-Tube® panels will be wrapped around the existing column with the protrusions facing towards the pile. The last panel is snapped in place to create a tube around the pile or column. The annular space between Form-A-Tube® and the pile is filled with grout or concrete. The protrusions will engage and lock into the freshly cast grout to form a unified structure. The Form-A-Tube® shell provides a beautiful smooth exterior surface and the shell will prevent moisture intrusion, the leading cause of corrosion.

In both applications, ratchet straps (or zip-ties) can be wrapped at 2-ft intervals along the height of the shell for added safety; these can be removed once the grout or concrete hardens.

Advantages of Form-A-Tube® :