Check out some photos from our recent events below:

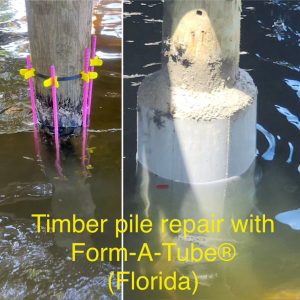

Below we have a simple demonstration of how Form-A-Tube® can be used to repair piles both on land and in water. Simply wrap the jacket around the deteriorated pile and fill it with concrete! As shown in the last two photos, zip ties may be used to ensure maximum support during the placement of concrete or grout.. Notice how multiple piles can be wrapped in Form-A-Tube® in an oval shape tube as the jobsite conditions require!

At the World of Concrete in Las Vegas in January 2019, Form-A-Tube® was introduced to visitors at QuakeWrap’s booth. This was the first time Form-A-Tube® was introduced to the public, and visitors were amazed as they further examined the product and its numerous applications.

The images below from a project completed in June 2019, show how Form-A-Tube® was used to encapsulate five corroded steel piles. The piles are 24 in. (600 mm) in diameter; the repair length was 14 ft (4.3 m) corresponding to the damaged portion of the pile at the splash zone. The Form-A-Tube® panels were special-ordered to a length of 14 feet. Fourteen panels were connected together to create a tube with a diameter of 28 in. (710 mm). The annular space between the tube and the steel pile was filled with grout.

Easy to Ship and Store:

Form-A-Tube® panels can be custom-ordered to any length. However, one of the main features of this product is that shorter pieces of various lengths can also be assembled (by staggering the joints like tiles) to create a tube of virtually any length. As sown here on the left image, by staggering the joints, 2-ft and 4-ft long panels are connected to build a 6-ft tall or even longer tube. The right image shows how 8-inch long pieces that are so easy to ship and store, can be assembled to create a longer tube.

This pallet contains 375 pieces of 8-ft (2.4 m) long Form-A-Tube strips; the total length of strips in this pallet is 3000 feet (900 m). This amount of materials can be used to build 62 tubes of 12-inch (300 mm) diameter, each 8-ft (2.4 m) tall, or 42 tubes of 18-inch (450 mm) diameter, each 8-ft (2.4 m) tall. Of course, unlike cardboard tubes that have a fixed length and diameter, there are virtually infinite combination of diameters and lengths of tubes that can be made with this single pallet of materials!